Making savings on utility bills while reducing environmental impact

“We have made savings while reducing our environmental impact by using less energy, alternative methods or recycling more”

What the company did

We are always working on improving our environmental impact. For example, we continually evaluate our waste and our energy usage. This allows us to make savings to the end utility bill but also allows us to reduce our environmental impact by using less energy, alternative methods or recycling more. Some particular projects that we have initiated include:

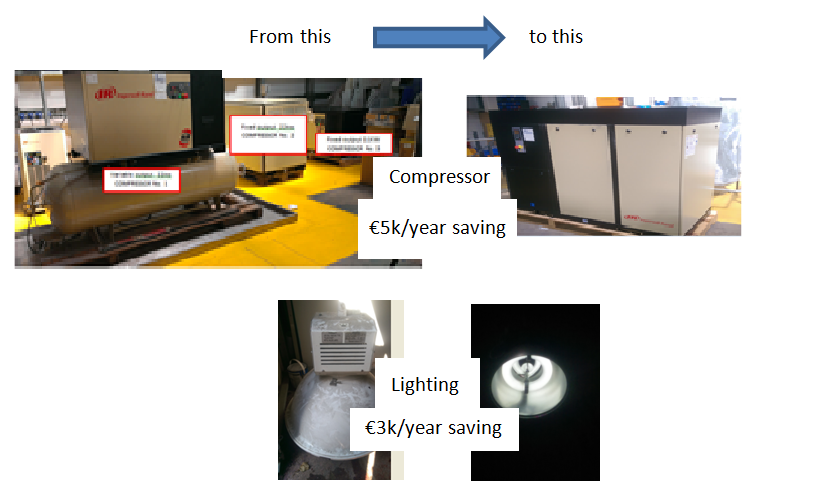

- Lighting: We replaced out our factory overhead lights.

- Equipment: We replaced out our main compressors to a variable speed compressor

- Processes: Numerous smaller projects in our machining processes and tooling

- Waste: Better segregation and some streams of waste recycling processing brought in house

Business Benefits

We have significantly gained financially reducing our overall costs in different ways including

- Lighting project: €3000 saving per year in power usage

- Compressor project: €5000 saving per year while also avoiding creating unused energy and waste air in the process

- Processes:

- Huge reductions in our machining times including the energy needed to manufacture them in some cases ( Through improved programing and new improved tooling

- Reducing production times by as much as 60- 80% makes sure we impact the environment less during manufacture but then also improve our efficiency( primarily through new tooling )

- Increase in machine life cycle time

- Waste:

- Reduction in courier costs and associated pollution

- Allowed us to control the processes and the chemicals used to ensure the most environmentally friendly are used where possible

The company

TEG is a specialist engineering services’ company providing tailor made solutions to the aviation, biopharmaceutical and pharmaceutical industries. Headquartered in Ireland, the company supports clients in over 30 countries with fast and effective solutions.

As an EASA Part 21(G) approved production organization, TEG is approved to manufacture new aircraft parts up to and including primary structural elements for aircraft. Such responsibility and accountability requires a high level of discipline, expertise and training.

The same techniques are used by TEG to supply the biopharmaceutical and pharmaceutical industry with custom designed wash racks for sterile fill parts and format change parts for solid dose blister packing.

The expertise of TEG is now widely recognized by customers, who value the relationship established over many years and appreciate the culture of customer support and business partnership. The tag line of TEG is ‘We are integral’. Many customers will attest to that based upon personal experience.

Check out TEG’s sustainability report here